| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Place of Origin : Jiangsu, China (Mainland)

Brand Name : Boqiao

Certification : CE/ISO9001

Supply Ability : 100 Set/Sets per Month

Packaging Details : Packaging details:One set per wooden case,or as required package

MOQ : 1 Set/Sets

Price : negotiable

Condition : New

Voltage : 380V

Power(W) : 5.5KW

Dimension(L*W*H) : 700*700 mm

Weight : Customized Dimension

Product name : Tiltable gravity casting machine

Application : Aluminum holder/intake manifold and other casting

Usage : Produce all kinds of complex aluminum products

System pressure : 10Mpa

Design : OEM & ODM

Max temperature : 900C

Operation syetem : Simens PLC automatic system

After-sales Service Provided : Engineers available to service machinery overseas

Warranty : One Year

Port : ShangHai

aluminum alloy holder/intake manifold and other casting gravity die casting machine

Product features introduction:

Flip angle 0-90° arbitrarily set

Real-time display with human-machine interface

Menu input, wide range of process parameters

Smooth operation, adjustable flip speed and angle

Reasonable design and easy operation

Compared to sand casting, metal casting has the following advantages:

1.The metal type has large thermal conductivity and heat capacity, the cooling rate of the molten metal is fast, the structure of the casting is dense, and the mechanical properties are higher than that of the sand casting. For example, the tensile strength of the aluminum alloy casting can be increased by 10%-20%, and the elongation is improved doubled.

2.Can obtain castings with high dimensional accuracy and good surface quality.

3.It can produce castings with complex internal cavity structure, such as engine block, cylinder head, wheel hub and so on.

4.Easy to automate and mechanize, high production efficiency

| Parameter | Unit | ZJ750 | ZJ860 | ZJ1210 |

| Dual active plate size | mm | 700*500 | 800*600 | 1200*1000 |

| Main mold opening and closing stroke | mm | 600 | 600 | 800 |

| Main model hydraulic cylinder bore | mm | 150 | 150 | 200 |

| Secondary mold opening and closing stroke | mm | 100 | 100 | 150 |

| Auxiliary mold hydraulic cylinder bore | mm | 150 | 150 | 200 |

| before and after the additional cylinder template size | mm | 300*400 | 300*400 | 500*600 |

| before and after the additional mold stroke | mm | 150 | 150 | 200 |

| before and after the cylinder bore | mm | 125 | 125 | 180 |

| the main mold vice mold minimum closure and maximum open Distance | mm | 400*1100 | 500*1200 | 900*1600 |

| tilt angle | ° | 0-90 | 0-90 | 0-90 |

| tilt cylinder bore | mm | 100 | 100 | 150 |

|

|

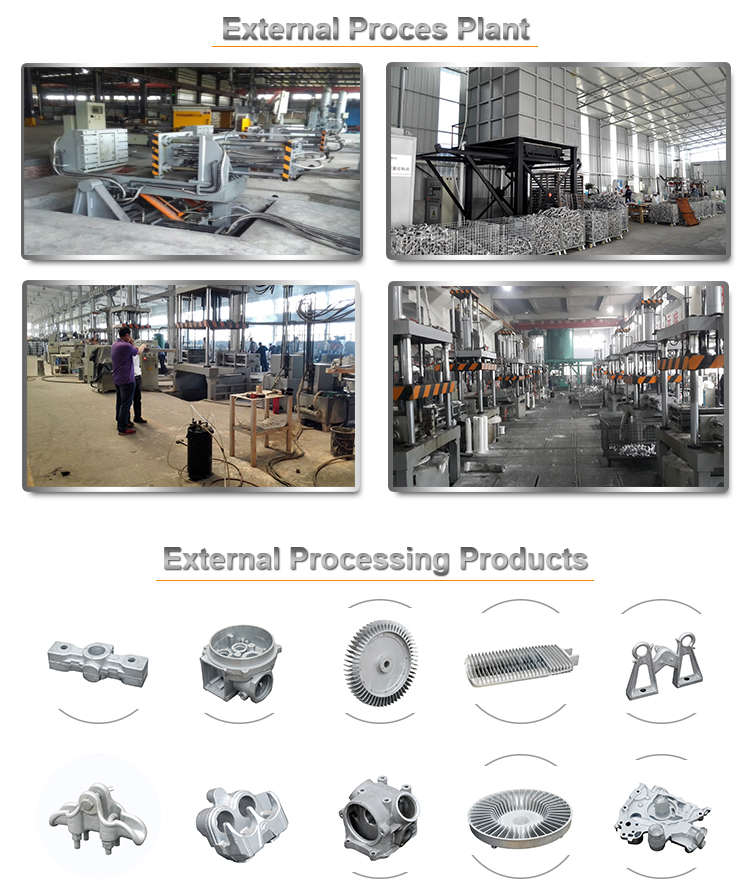

PLC Automatic Gravity Die Casting Machine For Aluminum Alloy Holder / Intake Manifold Images |